How to Use Calcium Carbonate Powder Effectively?

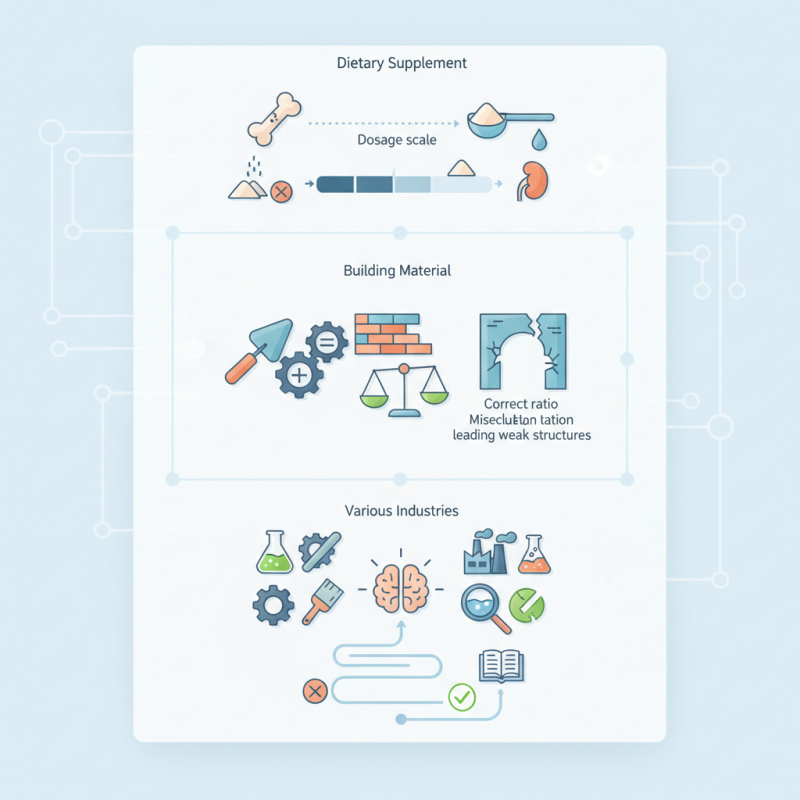

calcium carbonate powder is a versatile substance widely used in various applications. It serves as a dietary supplement, a building material, and a filler in numerous products. Understanding how to use calcium carbonate powder effectively can significantly enhance its benefits.

In dietary contexts, calcium carbonate powder is often recommended for bone health. Taking the right dosage is crucial. Too much can lead to kidney problems. In construction, this powder acts as a critical ingredient in concrete and mortar. Mixing ratios should be followed carefully to ensure strength and stability. Yet, inexperienced users can easily miscalculate these, leading to weak structures.

Many industries consider calcium carbonate powder essential. However, using it effectively requires knowledge and practice. Observing its interactions with other materials is also important. Users should remain open to adjustments and learning. Mistakes can happen, but they provide valuable lessons.

What is Calcium Carbonate Powder and Its Common Uses?

Calcium carbonate powder is a versatile compound widely used in various industries. It serves as a key ingredient in construction, plastics, and food industries. According to a recent report by the U.S. Geological Survey, the demand for calcium carbonate in the United States reached approximately 3.5 million tons in 2021. This highlights its importance in both industrial and consumer applications.

In construction, calcium carbonate is essential as a filler in cement and concrete. It improves strength and durability while reducing costs. The paint industry also relies on this compound, using it as a pigment and a filler to enhance texture. Interestingly, many people may not realize that it is found in over-the-counter antacids and dietary supplements. Its presence in everyday products raises questions about quality standards and sourcing practices.

Despite its numerous applications, the mining and production of calcium carbonate can pose environmental challenges. Some companies in the industry struggle with balancing economic efficiency and sustainable practices. This reflection on sustainability is crucial as industries strive for innovation while facing regulatory pressures. Continued research and commitment to responsible sourcing are vital for future growth and environmental stewardship.

Calcium Carbonate Powder Uses and Consumption Trends

This bar chart represents the global usage of calcium carbonate powder across various industries, showing its significance as a versatile material.

Understanding the Different Forms of Calcium Carbonate Powder

Calcium carbonate powder comes in several forms, transforming how we use it. The most common is ground calcium carbonate (GCC). This form is often used in construction, agriculture, and as a filler in products. Its fine texture allows for easy incorporation into various materials. It helps in enhancing product durability and longevity.

Another form is precipitated calcium carbonate (PCC). This variant is produced through a chemical reaction, resulting in purer particles. It's commonly used in the food and pharmaceutical industries. The specific properties of PCC make it ideal for controlled applications. However, it can be more expensive than GCC, which requires careful consideration.

Lastly, there’s nanoscale calcium carbonate. This form has unique properties due to its size. It’s often utilized in advanced materials and coatings. While it offers impressive benefits, the handling requires additional safety measures. Many users overlook this aspect, leading to safety issues during application. Reflecting on the method of use can help avoid such pitfalls.

Step-by-Step Guide to Measuring and Mixing Calcium Carbonate Powder

When measuring calcium carbonate powder, accuracy is key. Begin by using a precise scale. An average user may underestimate the weight, leading to imprecise mixtures. The right amount can make a big difference. For instance, industry reports suggest that using 50 grams of calcium carbonate per liter achieves optimal results in many applications.

Mixing is equally important. Use a clean, dry container for blending. A common mistake is to add water too soon. Keep the powder dry until fully combined. Stir gently but thoroughly to avoid clumping. A flawed mixture can impact performance and effectiveness. Industry findings highlight that uneven mixtures can reduce the efficacy by up to 20%.

Pay attention to the texture of the mixture. It should be smooth and free of lumps. If you notice pellets forming, reconsider your mixing technique. A more methodical approach may be needed. Users often overlook the importance of mixing time. A rushed process could lead to inadequate dissolution, which ultimately affects the final product.

Best Practices for Storing Calcium Carbonate Powder Properly

Storing calcium carbonate powder properly is vital for maintaining its quality and effectiveness. First, keep it in a cool, dry place. Moisture can cause the powder to clump. Use airtight containers to prevent exposure to air. Light and humidity can degrade the powder over time. A dark cupboard works well for storage.

Regularly check your supply. Discard any powder that appears discolored or has an unusual texture. It’s crucial to label containers with dates. This helps you track freshness. Avoid storing calcium carbonate near strong odors. It can absorb unwanted scents, affecting its usefulness.

Remember, not everyone gets storage right. Many overlook temperature fluctuations. Extreme cold or heat can alter its properties. Take time to assess your storage habits. Adjust as needed. Small changes can make a big difference. Proper storage ensures that you get the best results when you use calcium carbonate powder.

Safety Precautions When Handling Calcium Carbonate Powder

Handling calcium carbonate powder requires careful attention to safety precautions. According to the National Institute for Occupational Safety and Health (NIOSH), exposure limits for respirable dust should not exceed 5 milligrams per cubic meter in an 8-hour work shift. Inhalation can cause respiratory issues. It's crucial to use proper ventilation in workspaces. Wearing a mask can protect against inhaling fine particles.

Always wear eye protection to prevent irritation. Fine particles can easily enter the eyes, causing discomfort. Laboratory studies show that calcium carbonate can cause mild skin irritation upon contact. Thus, wearing gloves is advisable. The American Conference of Governmental and Industrial Hygienists (ACGIH) suggests that skin exposure should be minimized. Ensure to wash hands thoroughly after handling the powder.

In storage, keep the powder in a tightly sealed container. Unsealed containers can lead to dust accumulation, which poses a health risk. Regular cleaning of work surfaces is essential to minimize dust exposure. Recognizing these risks is vital for safety. Not all safety measures are foolproof. It's easy to overlook small details, leading to potential accidents. Regular training and awareness can help Keep everyone safe.