How to Choose the Right Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh can be challenging. Experts often highlight key factors to consider. John Smith, a leading authority in the industry, advises, "Selecting the correct mesh ensures structural integrity and longevity." The options available today can be overwhelming.

When considering stainless steel woven wire mesh, it’s essential to think about application and material grade. Different projects require different specifications. For example, food processing plants need mesh that meets health standards. The weave pattern also plays a crucial role. Tight weaves offer better filtration, while looser weaves provide airflow.

Many overlook the importance of durability. Not all stainless steel is created equal. High-quality mesh resists corrosion and wear. However, budget constraints often lead to compromises. This can result in frequent replacements, creating higher costs over time. Reflecting on these details can lead to better choices in stainless steel woven wire mesh.

Understanding the Different Types of Stainless Steel Woven Wire Mesh

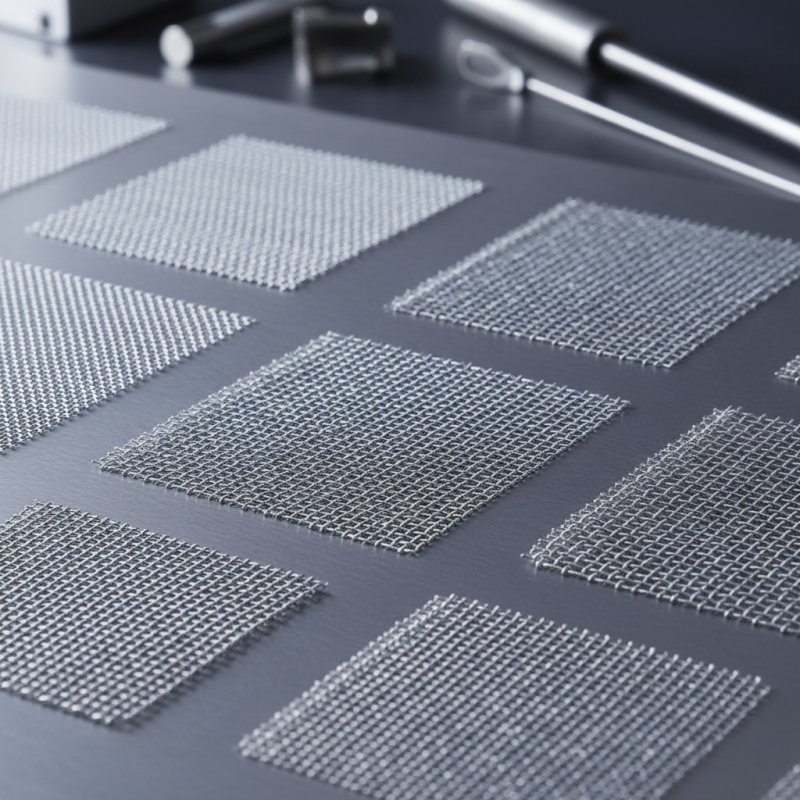

When selecting stainless steel woven wire mesh, it’s crucial to understand the different types available. Common types include plain weave, twill weave, and Dutch weave. Each type has unique properties that can influence your choice.

Plain weave mesh is simple and versatile. It’s suitable for general applications. Twill weave offers greater strength and flexibility. It has a more complex pattern. This makes it ideal for applications requiring durability. Dutch weave, on the other hand, is tighter and offers high filtration capabilities. It is perfect for fine particulate separation.

Each type has its pros and cons. Choosing one can be challenging. Assessing your specific needs is vital. Consider factors like wire diameter and mesh count. You may have to rethink your options several times. Personal experiences often lead to better decisions. A good fit involves balancing strength, flexibility, and filtration needs. Every detail matters.

Key Factors to Consider When Selecting Stainless Steel Wire Mesh

When selecting stainless steel woven wire mesh, consider several key factors. The mesh size is crucial. Smaller openings provide better filtration but may restrict airflow. Choose a size that fits your application needs. Wire diameter also matters. Thicker wires offer enhanced strength but can lead to reduced flexibility.

Tips: Think about the environment. Will the mesh face harsh weather? High corrosion resistance is essential in such cases. Assess the mesh's weave type as well. Different weaves can affect both appearance and performance.

Additionally, the intended use can influence your choice. Some applications require specific material grades. High-quality stainless steel can resist rust and damage. Measure your requirements carefully. Sometimes, the perfect match isn't as straightforward as it seems. Double-check before making a final decision.

Evaluating the Applications and Uses of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is versatile and widely used. It serves in various industries, including construction, agriculture, and food processing. For example, in construction, this mesh is often utilized for reinforcement. Its strength and durability ensure stability in structural applications. Similarly, in agriculture, it is seen in fencing and pest control systems. The mesh effectively keeps animals out while allowing air and light to pass through.

Choosing the right mesh depends on specific needs. Considerations such as wire diameter, mesh opening, and weave type matter. A finer mesh may be ideal for filtration purposes. However, it could restrict airflow in other applications. Larger openings might be better suited for structural support, yet may not filter as effectively. Evaluating the intended use is crucial. Sometimes, it may seem impossible to choose without a clear understanding of the requirements.

In food processing, hygiene is a priority. Stainless steel offers corrosion resistance and easy cleaning. This feature is vital for maintaining food safety standards. Yet, one should reflect on the mesh's longevity in harsh conditions. Over time, even stainless steel can show signs of wear. Understanding these nuances helps in making informed decisions.

Comparing Stainless Steel Grades for Woven Wire Mesh Selection

When selecting stainless steel woven wire mesh, understanding the different grades is crucial. Each grade has unique properties that impact performance. For instance, 304 stainless steel is common for general applications. It's resistant to corrosion but may not withstand high temperatures. Meanwhile, 316 stainless steel offers enhanced corrosion resistance, making it ideal for marine environments.

Another factor to consider is the wire diameter. Thicker wires provide superior strength but less flexibility. However, finer meshes can allow for more precise filtration. It’s not just about the strength; the mesh opening size is also crucial, affecting airflow and material retention.

While many assume a higher grade means better quality, that's not always true. Each application has different requirements. Make sure to assess your specific needs. Where will the mesh be used? What substances will it come into contact with? Reflecting on these questions can lead to a more informed choice.

Tips for Maintaining and Caring for Stainless Steel Woven Wire Mesh

Maintaining stainless steel woven wire mesh requires a solid understanding of its properties and the environment it lives in. Stainless steel has resistance to rust and corrosion, but it’s not invincible. In high-humidity areas, oxidation can still occur. A study by the American Society for Metals indicates that corrosion rates can increase by 10-30% in coastal regions due to salt exposure. Regular cleaning is vital. Use mild detergents and avoid abrasive cleaners.

Inspecting mesh regularly is crucial. Look for any signs of wear or tear, even minor changes. Neglected mesh can lead to larger issues. Some studies show that over 50% of industrial wear failures happen due to inadequate maintenance. Pay attention to the installation area, as debris can accumulate and cause rusting. Even small particles can cause significant damage over time. It’s essential to keep the environment in check.

Consider storage as well. If the mesh is not in use, store it in a dry place. Moisture and dust can lead to deterioration. Reports from industry experts suggest that improper storage can reduce the lifespan of stainless steel wire mesh by up to 40%. By attending to these details, you can extend the life of your stainless steel woven wire mesh, ensuring it performs effectively.